The ABB GoFa CRB 15000 is a collaborative robot (cobot) designed to work safely alongside human workers without the need for physical barriers. With its sleek design and advanced safety features, GoFa maximizes flexibility and efficiency in various applications, from assembly and machine tending to palletizing and screwdriving.

Strong yet safe: GoFa is capable of handling payloads up to 12 kg and integrates torque sensors in each of its six joints, offering superior power and force-limiting performance. This ensures that GoFa can stop immediately if it comes into contact with a human, reducing the risk of injury. The robot's design includes rounded geometry with no pinch points, further enhancing safety.

Faster performance for greater productivity: GoFa boasts a maximum Tool Center Point (TCP) speed of up to 2.2 m/s, making it faster than many other cobots in its class. This speed, combined with a reach of up to 1.62 meters and a repeatability of 0.02 mm, allows GoFa to perform more operations within a set period, increasing productivity and efficiency in various tasks.

Easy setup and operation: The GoFa CRB 15000 is designed for user-friendliness with features like lead-through programming, an intuitive FlexPendant interface, and ABB’s Wizard Easy Programming. These features enable even first-time users to set up and operate the robot quickly and efficiently, minimizing downtime and maximizing usability.

GoFa is powered by ABB’s OmniCore controller, known for its high performance, flexibility, and ease of integration with modern production technologies. This combination of advanced features and user-centric design makes the ABB GoFa CRB 15000 a versatile and efficient solution for collaborative robotics needs in diverse industrial environments.

| Reach (mm) | 950(wrist) 1050 (flange) |

| Payload (kg) | 5 |

| Arm load | 1 (mounted on axis 4) |

| Number of axes | 6 |

| Protection | IP54 |

| Mounting | Angle,wall,floor & ceiling |

| Controller | OmniCore C30 |

| Power supply | 24V/2A supply |

| Customer signals | 4 signals (for IO, Fieldbus or Ethernet) |

| Tool flange | Standard ISO 9409-1-50 |

| Functional safety | SafeMove Collaborative (certified to category 3), PL d |

| Max TCP Velocity | 2,2 m/s |

| Max TCP Acceleration (controlled motion for nominal load) |

36,9 m/s2 |

| Max TCP Acceleration (e-stop for nominal load) |

61,6 m/s2 |

| Repeatability | 0,02 mm |

| Weight | 28kg |

Axis movement |

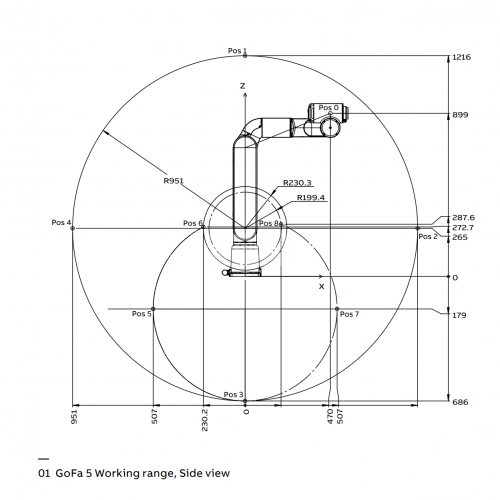

Working range |

Axis max.speed |

| Axis 1 rotation | -180º to +180º | 125º/s |

| Axis 2 arm | -180º to +180º | 125º/s |

| Axis 3 arm | -225º to +85º | 140º/s |

| Axis 4 wrist | -180º to +180º | 200º/s |

| Axis 5 bend | -180º to +180º | 200º/s |

| Axis 6 turn | -270º to +270º | 200º/s |

Applications

Loading and unloading of parts , Machining , Handling of parts , Measurement , Assembly of parts , Glueing - Adhesive bonding , 3C Electronics , Advanced Manufacturing , Education

Pictures

Diagrams